INTRODUCTION

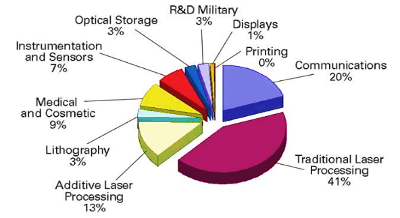

Recently, the development of new laser systems for industrial needs has increased. Many new processes were developed, and many traditional industrial processes were replaced by laser additive systems. Material processing accounts for a significant share of the total laser market, as shown in the figure below:

Figure 1. Worldwide laser applications1

Diffractive optical elements (DOEs) play an important role in provision of the process-adapted laser beam shaping. This has made laser beam shaping and homogenization techniques essential to optimize many laser-material processing applications.

Usually, laser systems start from utilizing the laser, and performance is upgraded by adding a DOE.

The key parameters achieved are:

- Multiplying process speed and throughput

- Process precision

- Wall steepness

- Heat affected zone

- Process effectiveness

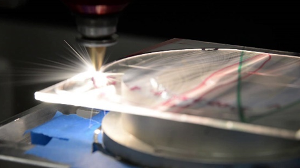

Ablation & Structuring

Laser ablation is the process of removing material from a solid (or occasionally liquid) surface by irradiating it with a laser beam. Ablation is achieved by applying high energy short pulses on a small area.

Laser ablation has been considered and used for many technical applications, including: the production of Nano materials, deposition of thin metallic and dielectric films, fabrication of superconducting materials, routine welding and bonding of metal parts, and micromachining of MEMS structures.

Holo/Or’s Top-Hat and Vortex-Lens produce shaped spots with sharp, defined edges that will produce a precise material removal in the ablation process. Multi-Spot elements enable parallel processing, thus increasing throughput.

Relevant products:Top Hat, Vortex lens, Multispot

Figure 2. Laser ablation

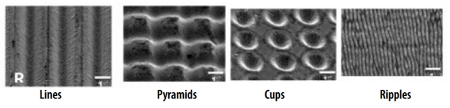

Figure 3. Laser structuring2

Welding

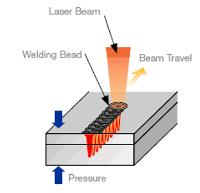

Laser welding techniques are used to join multiple pieces of metal or plastic with a laser. The beam provides a concentrated heat source, allowing for narrow, deep welds and high welding rates. The process is frequently used in high volume applications using automation, such as the automotive industry. In conjugation with cutting techniques, lasers are ideally suited for many types of welding (spots, line, soldering).

Holo/Or’s Homogenizer elements have uniform, flat intensity profiles regardless of non-homogeneity in the input, and can be designed to give shaped distributions that are tailored for specific welding profiles. Using a trailing spots multi spot profile, one can pre-heat the weld area and then post-treat it.

Relevant products: Homogenizer/Diffuser, Multispot, C shaper, High efficiency double spot

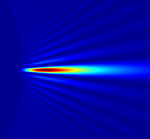

Figure 4. Laser welding3

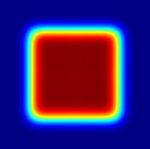

Figure 5. Homogenizer energy distribution

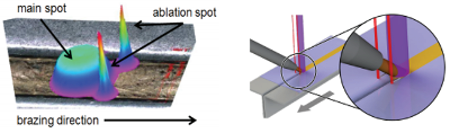

Brazing

In laser brazing applications, two metal sheets are joined by a laser melted solder wire. The join quality has been proven to improve when the metal surfaces are cleaned and pre-heated before the brazing wire is melted. Typical applications are found in the automotive industry.

For this purpose, Holo/Or has developed a special Homogenizer element that creates two small leading beams for cleaning/preheating and one large uniform beam that equally distributes the energy over the brazing wire to achieve better melting and cleaner edges.

Relevant products: Custom Homogenizer — please contact Holo/Or for more information

Figure 6. Laser ablation process

Figure 7. Energy distribution of custom homogenizer

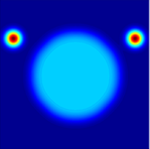

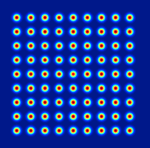

Perforation

A perforation is a small hole in a thin material or web. Laser perforation is typically used for sheet materials such as cigarette-tip paper or packaging foil for the food industry (prolongs the freshness and quality of perishable goods).

Such applications require precise microscopic holes of a desired pattern with equal distances. This is why Holo/Or’s beam-splitter DOE are the obvious solution.

Relevant products: Multispot

Figure 8. Laser perforation for food packaging4

Figure 9. 9×9 multi-spot beam splitter

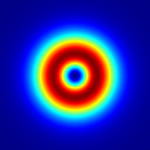

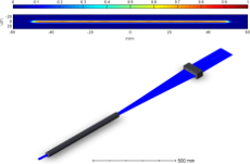

Cutting (metal & glass)

Laser cutting works by directing the output of a high-power laser, usually through an optical system & moving stage, to scan the focus on a workpiece and cut it. It is typically used in industrial manufacturing applications. The goal is to extend the depth of focus of the system, without increasing the focal length of the focusing optic, or to improve cut quality and reduce exfoliation and material re-melting in the cut area.

Metal laser cutting is performed by locally heating the material at the focal point of a focused laser beam above its melting point. The resulting molten material is ejected by a gas flow, so that an open cut is formed.

Glass laser cutting or laser dicing is usually done with high powered lasers in the IR regime. Because glass has a weak absorption of light in most wavelengths, more powerful lasers are needed to cut glass. By using a focal DOE, the energy is spread in the bulk of the glass wafer. This enables one-pass cuts, without the need of adjusting the focal depth of the spot and z-movement during the cut. This is especially useful for stealth dicing, where the laser light modifies the glass to make it brittle, instead of ablation cutting, and then the glass is mechanically separated along the laser process line.

Relevant products: for metal cutting — Vortex Lens, Top Hat; for glass cutting — DeepCleave Module, Elongated Focus, Multi-focal Lens

Figure 10. Laser metal cutting5

Figure 11. Vortex lens energy distribution

Figure 12. Laser glass cutting6

Figure 13. Elongated focus energy distribution along optical axis

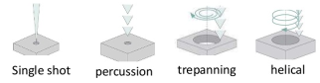

Drilling

Laser drilling is the process of creating thru-holes by repeatedly pulsing focused laser energy on a material and evaporating the melted material. The greater the pulse energy, the more material is melted and vaporized. Over the years, several laser drilling techniques have evolved, including signal pulse, percussion, trepanning and helical drilling. Laser-drilled holes are used in many applications, including drilling of silicon wafers and rubber.

For higher throughput and more productive processes, Holo/Or’s Multi-Spot beam-splitters have been proven to provide accurate results. Top-Hat beam shapers can improve the edge quality and diameter accuracy of the holes, while vortex phase plates enable drilling of ring shapes.

Relevant products: Multispot, Top Hat, Vortex lens

Figure 14. Different laser drilling techniques7

Figure 15. Laser micro-drilling of stainless steel tube8

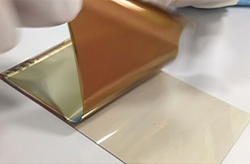

Laser Lift-Off

Laser Lift Off (LLO) is a technique to selectively remove one material from another. A laser beam is projected through a transparent material and absorbed in an adjacent material on the backside, such as GaN on Sapphire. The laser lift-off separation process allows processing large area devices with the required finesse and reproducibility. For this reason, it is very common in the LED industry for separating light-emitting films and also in displays for television and mobile devices.

LeanLine™ is Holo/Or’s innovative solution for transformation of a Multi-Mode round input beam into a narrow laser line, especially in UV and green wavelengths (343, 355, and 532 nm). Our solution is based on proprietary diffractive beam shaping concepts and can be tailored to any wavelength from 193nm deep UV to 1600nm IR lasers. By utilizing our solution, one can use lower cost Multi-Mode lasers to achieve an efficient power density in a thin line.

Relevant products: LeanLineTM module

Figure 16. Holo/Or’s LeanLineTM module

Figure 17. Separation of a substrate from a glass panel

Surface treatment (hardening & remelting)

The principle of laser surface treatment is the modification of a surface as a result of interaction between a beam of high power density coherent light and the surface within a specified atmosphere (vacuum, protective or processing gases). Some of the typical uses of laser surface treatment are laser hardening and laser re-melting.

Laser hardening is a thermal surface hardening process in which the material is heated up for a short time above the critical temperature and is then rapidly cooled down, preventing the metal lattice from returning to its original structure and producing a very hard metal structure.

Laser re-melting is another thermal method of surface treatment. The component surface is briefly heated above the melting temperature. The melt then solidifies and re-crystalizes without major changes in the chemical composition.

Relevant products: Homogenizer/Diffuser, Top Hat

Figure 18. Laser hardening

References

- https://www.photonics.com/Article.aspx?AID=60946

- Jens Bliedtner et. al, “Ultrashort Pulse Laser Material Processing”, Laser Technik Journal

- http://www.avio.co.jp/english/products/assem/lineup/laser/yag.html

- http://elenlaser.com/co2-laser-applications/plastic-film.html

- http://www.acsys.de/en/laser-cutting/laser-fusion-cutting.html

- https://www.youtube.com/watch?v=-S7GvYepCPo

- https://www.slideshare.net/kokoisawesame/laser-drilling-47644341

- http://kjlasermicromachining.com/portfolio-posts/laser-micro-drilling-stainless-steel-tube/